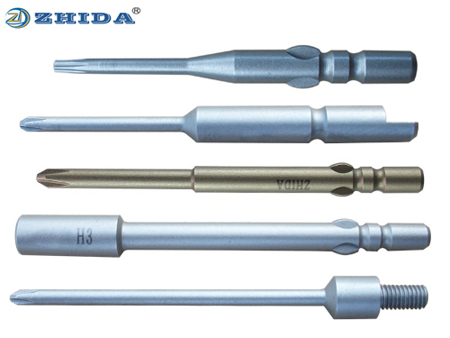

Screwdriver Bits, alias screw bits, driver bits, according used type can sort electric driver bits type, air pneumatic driver bits type and manual operation type. Now is lot driver bits brand in the market, price and quality are different so far. Sometimes maybe let customer confuse and don’t know how to choice. Certainly the Japan’s brand and Germany’s brand quality is good, but the price are higher, nowadays economy environment is not good, manpower cost is high lead to the material high too, All enterprise need to reduce produce cost to operate.

But high quality Screw Bits non other choice expect

1. The Screw Bits material. Material is the basic for decide the screw bits’s quality. Nowadays the best steel to produce screwdriver bits’s material is

2. The Screwdriver Bits heat treatment technology. Heat treatment can promote the steel’s chemical properties, can give play the steel’s best torque to promote the driver bits quality. Each manufacturer’s heat treatment technology is different, and is commercial secret.

3. The Screwdriver Bits machining accuracy. The driver bits’s size accuracy effect the bits service time direct. The same screw, if use a cheap driver bits to insert, maybe you’ll found the goodness of fit is not good, and very loose, then you’ll know the bits quality and not need to test, Our ZHIDA’s driver bits head size not only compliant the DIN’s gages, our machining accuracy can under control in 0.02mm, and projective each bits’s head size, Special for the small precision driver bit size, is easy broken and transformation when it produce, that’s same level for Germany’s brand.

4. Screwdriver Bits shank concentricity correction.